![]() Please call us ! 📞

Please call us ! 📞

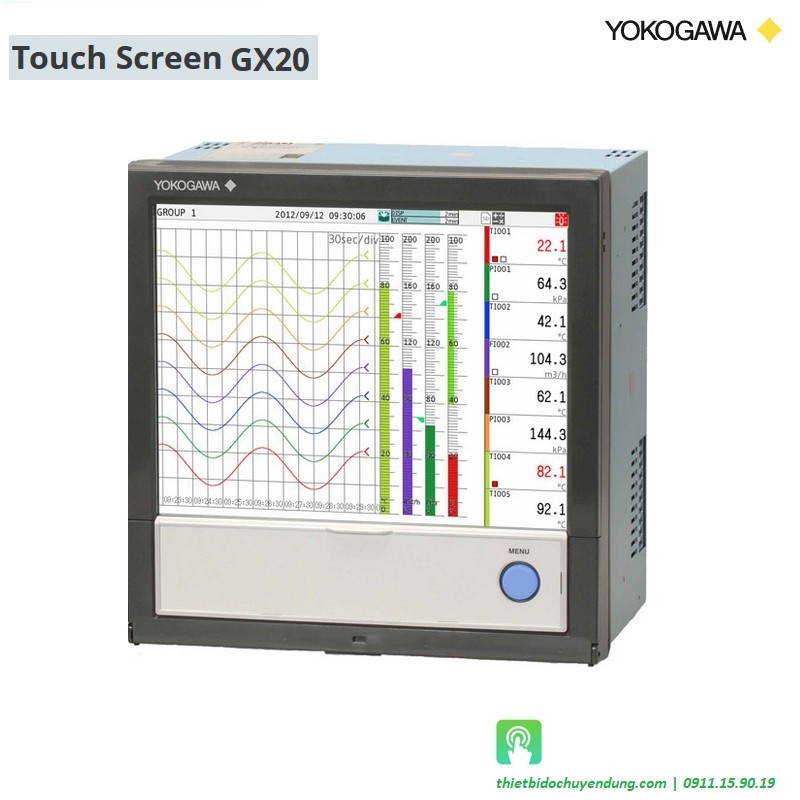

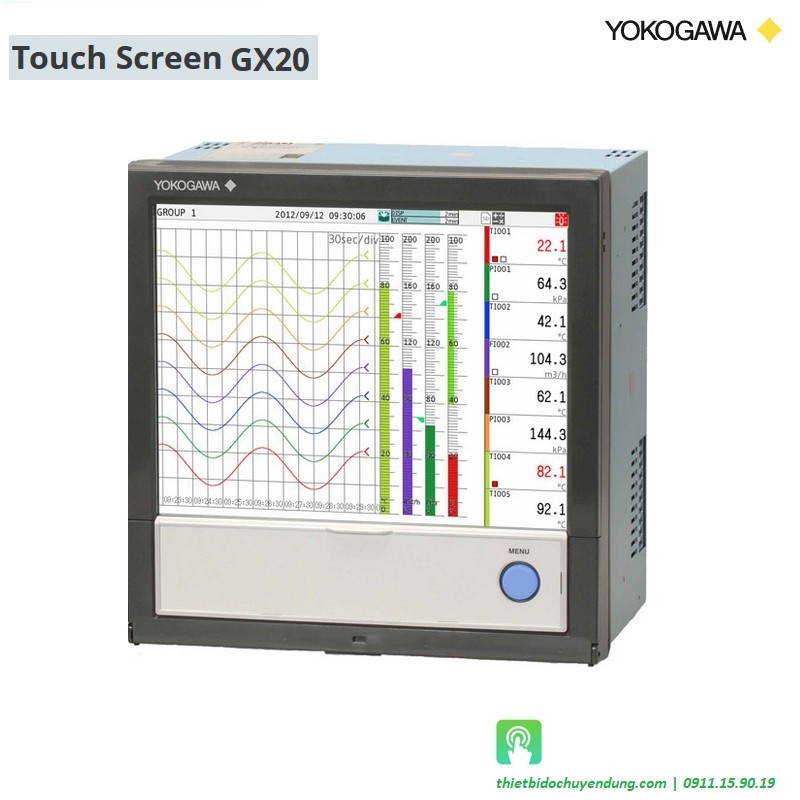

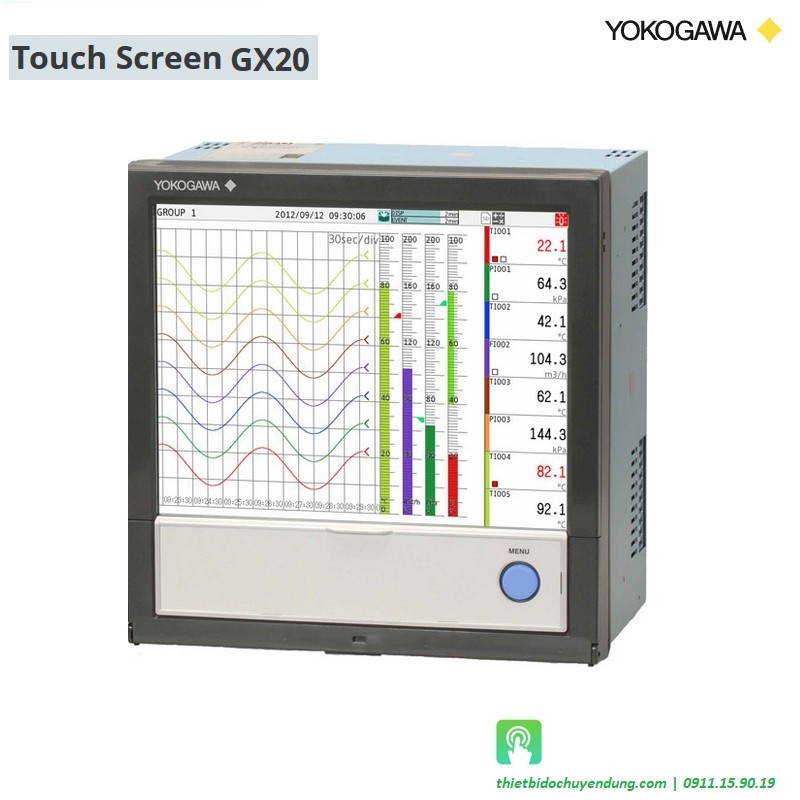

✅ Main unit alone provides up to 100 channels (GX20), expandable to up to 450 channels

✅ Real time remote monitoring from a web browser

✅ Provides safe and traceable data management in applications such as pharmaceutical manufacturing, biotechnology, health management and medical institutions

✅ Advanced security function supports the strict requirements of US FDA 21 CFR Part 11, EU-GMP Annex 11

✅ Wide variety of input/output modules support input DCV, thermocouple (TC), RTD, 4-wire RTD, 4-wire resistance, contact, Pulse signal

Hotline: 0911.159.019

Email: sales@thietbidochuyendung.com

|

The GX series is an industry-first multi-point touch panel, to improve intuitive and smart operator control. Users can scroll, pan, zoom historical data, and even write freehand messages on its dust-proof and water-proof display. The Yokogawa GX series delivers industry leading reliability and measurement accuracy. Its custom graphics accommodates application or process-specific displays, while a wide range of communication protocols guarantee compatibility with your network architecture. It's simple for operators to view and retrieve past data with automatic email and FTP notifications

Application Note

|

An intuitive UI engineered for ease-of-use

|

Seamless display of historical trends—flick or drag the trend display to scroll through the data, even during measurement

From a calendar, jump to waveforms of a specific date. From the alarm summary, jump to the waveform active during the alarm

Immediately clear areas of concern with a hand-written message.

You can draw or hand-write on the waveform area using a stylus (standard accessory) or the tip of your finger. You can even select a color and line width. Alternatively, you can select from a list of preset messages

Save trend waveforms of interest or screens displayed during alarms as image (PNG) files, and print them out at the same time. |

Long-duration trends can be fitted to a single screen for easy viewing

The time axis and engineering axis can expanded and compressed using a simple pinch together or apart function

You can arrange display objects such as trend, numeric, and bar graphs any way you like to create monitor displays that are customized to the environment. Start/stop pumps and perform other operations

You can select from 9 layouts, and save up to 20 configurations. (Multi panel available on the GX 20 only) G X 20

|

|---|

Highly flexible and scalable architecture

|

Inputs and outputs are modular for easy expandability. The GX multichannel paperless recorder main unit alone provides up to 100 channels (GX20) of measurement

Analog input moudule: DC voltage, DC current thermocouple, RTD, contact, DC current (mA), 4-wire RTD, 4-wire resistance Digital input mudule: Remote control input or operation recording Pulse input module: Pulse signal data acquisition, integral count Analog output module (current output), Digital output module (alarm output); PID control module (PID control 2 loops) Digital input/output module: Remote control input or operation recording/alarm output |

Supports up to 450 channels of measurement. Note that if MATH and communication channels are included, the GX 20 large memory type can record on up to 1000 channels. The GX main unit and expandable I/O can both use the same input/output modules

When the recorder is installed offsite (away from the DUT), you can place the expandable I/O at the site and monitor data without the need for long-distance wiring of thermocouples and other sensors

|

|---|

A full range of network functions and software

|

New! Built-in AI function to predict the future AI comes standard on the GX/GP

Use acquired data to predict future data, and display predicted future waveforms along with real time data on the trend monitor. Predicted future waveforms help you identify and deal with likely problems as soon as possible.

You can set future alarms based on future data predicted by the future pen. You can check future alarm information in the Future Alarm Summary screen. Also, when a future alarm occurs, notification can be sent by external (digital) output or email. Because the future alarm information also includes the predicted alarm time, you can also identify the urgency

Through a Web browser you can monitor the GX in real time and change settings. You can easily build a seamless, low-cost remote monitoring system with no additional software.

Calibration correction schedule control function (/AH option)

Schedule management for periodically executing calibration correction configuration and the like. The correction factor can be set separately for unit and sensor dependency. For AMS2750, we offer TUS software* that can easily create TUS (temperature distribution test) reports.*.

Multi-batch Function (/BT option) Recorder pre-defined channel groups to separate data files with independent start and stop control. Up to 12 independent batches can be created |

Control function. Enables PID and program control

High speed (1 ms) measurement* Proprietary A/D converter With 1ch per module. At 2 ms, 2 ch per module, and at 5 ms or more, all 4 ch per module.

Users have the ability to choose two different scan intervals on a single GX/GP system. This allows users the flexibility to measure various types of inputs with two different scan intervals in a single system. For example, this provides for efficient, simultaneous measurement of signals with slow fluctuations such as temperature, and fast-changing signals such as pressure and vibration. Modules can be assigned to measurement groups.

MATH function (/MT option)

Supports various kinds of math computation, including basic math and functions (square root, logarithms, trigonometry). Write formulas using variables for measured or computed data and save or display the results—this saves time and effort on post-processing. Create hourly, daily, monthly, and other reports with the Report function.

|

|---|

Rock-solid hardware and highly secure

|

The front panel door can be locked to prevent mishandling of the power switch or external media.

For increased security, measured data can be saved in binary format. This format is very difficult to decipher or modify in traditional text editors or other programs. To enable easy and direct opening of the data in text editors or spreadsheet programs, choose text format. This allows you to work with your measurement data without dedicated software.

|

Measured and calculated data is continuously saved to secure, internal non-volatile memory. At manual or scheduled intervals, the files in memory are copied to the removable media. In addition, the files can be copied and archived to an FTP server

Because of the inherent reliability and security of non-volatile memory, the possibility of losing data under any operating condition or power failure event is extremely small

Safely sends and receives customer data.

SSL: An encryption protocol for data sent over TCP/IP networks |

|---|

Provides a variety of convenient networking functions

|

GX supports Modbus TCP/IP client and server modes for Ethernet communications and Modbus RTU master and slave modes for optional serial communications Modbus/TCP (Ethernet connection)

Modbus/RTU (RS-422/485 connection)

Using the EtherNet/IP server function, you can access the GX from a PLC or other device to read measurement/computation channels and write to communication input channels (GX10: up to 500ch, GX20-1: up to 300ch, GX20-2: up to 500ch). Communication channel function (/ MC option) is required.

Protocol function that enables connection from a GX to Mitsubishi Electric PLCs without sequencer programs. You can run the GX as an SLMP client, enabling writing of GX measured data to the PLC and writing of PLC data to communication channels. Requires the communication channel function (/MC option)

|

Highly precise measured data from power measuring instruments (WT series power analyzers WT310E | WT310EH | WT332E | WT333E | WT500 | WT1800E | WT5000) can be acquired without loss of fidelity on the GX, and recorded and displayed alongside the GX's own measured data. This is ideal for performance evaluation testing because you can record instrument power consumption, temperature, and other phenomena simultaneously

Data acquired by the GX can be accessed through Ethernet communication from a host system (OPC UA client). Writing from an upstream system to a GX communication channel requires the communication channel function (/MC option).

GX uses SNTP protocol in client mode to acquire time information from a network time-server. This function allows any number of GX units within a facility to have precisely synchronized time; all units will record data with coordinated date and time stamp information. In addition, GX can function as a server, providing time data to other SNTP client units on the network.

|

|---|

A full range of network functions and software

A full range of network functions and software

|

Advanced security function option (/ AS) corresponding to strict requirements for data management SMARTDAC+ GX /GP/GM advanced security function option (/AS) provides safe and traceable data management in applications such as pharmaceutical manufacturing, biotechnology, health management and medical institutions. The advanced security function supports the strict requirements of US FDA 21 CFR Part 11, EU-GMP Annex 11 and other associated guidelines for data management. It also supports data integrity in accordance with ALCOA+ (Attributable, Legible, Contemporaneous, Original, Accurate, Complete, Consistent, Enduring, Available) mentioned in PIC/S, WHO, MHRA and FDA guidance documents

Measured data, settings, and operation logs, are saved to a single encoded binary file. Encoded data in binary format offers a high level of security because it cannot be opened in most text editors. If the data files are damaged or tampered with, SMARTDAC+ Standard Universal Viewer software will identify the nonconformity and notify the user according

Measurement data can be displayed and confirmed on the GX/GP (only the data in the internal memory) or the SMARTDAC+ Standard Universal Viewer software, and an electronic signature can be applied to that data. Three levels of signature are available: operator, supervisor and quality control. The signature along with information such as pass/fail and comments can be saved to the data for review and audit. |

Data integrity requires that the right users have access to the right information. SMARTDAC + can create users with various access privileges. Four main security levels (two separate administrator roles, user and monitor user). Up to 200 persons can be registered. Process owners/ s

The SMARTDAC+ operation log is saved to a file along with measurement data. When settings are changed, it is possible to record the reason for the change along with the setting change operation. In addition, checking the details of setting changes from "setting difference operation history" makes greatly reduces the data checking work during audits

Validation documentation (sold separately) is a validation protocol template that simplifies GX/GP/GM and SMARTDAC+ Standard system validation. The document is provided on the Yokogawa website as an MS Word file for easy editing.* |

|---|

Specification | Brochure | Manual Instruction